Moneyweb reports that Koeberg Unit 1, currently on planned maintenance, is set to return to service only in September [1]. The unit was initially supposed to be back online during the winter, but this has been moved out to spring.

Koeberg Unit 1 is just over 900MW in capacity. The planned maintenance on this unit demonstrates that baseload power is a concept that has reached its expiry date.

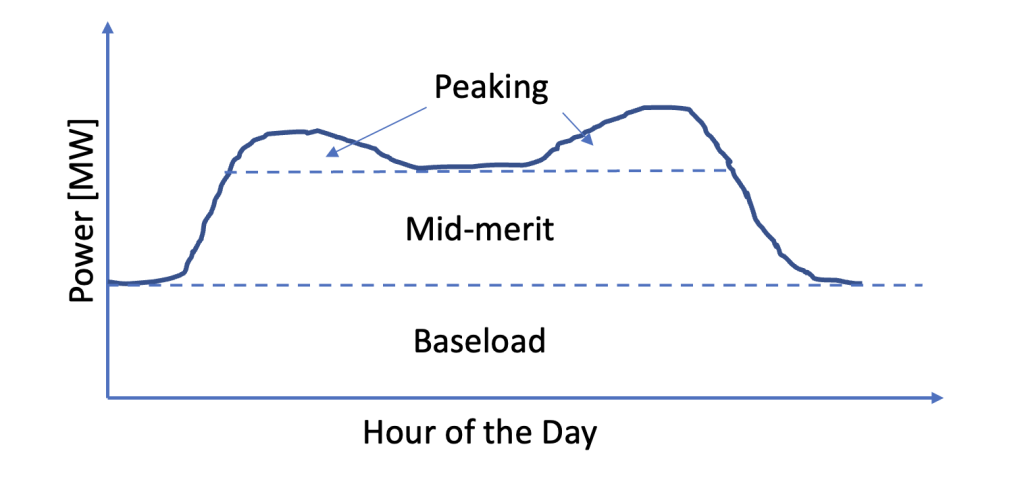

The Demand and Supply Curves

Consider a graph. In the y-axis, you have power (supply or demand). In the x-axis, you have the hour of the day. Baseload power provides power to the grid in large rectangular chunks on this graph. In the case of Koeberg’s unit 1, that rectangle has a height of 900 MW. When online, it stretches across the x-axis for 24-hour generation.

The first part of the problem is that the demand curve is not a rectangle. It has a minimum level yes, but ramps up for the morning peak, settles somewhat during the middle of the day to an upper minimum, peaks again in the late afternoon, and then settles again to the minimum when the country goes to sleep. Baseload power is only effective up to this overnight minimum.

We need alternative generation regimes for the morning ramp-up, the morning peak, the midday minimum, the evening ramp-up, and the evening peak. We need mid-merit and peaking generation. Mid-merit power stations can be switched on and off from day to day. Peaking power stations can be ramped up and down quickly in response to minute-by-minute changes in demand. The switching and the ramping do not have any negative effect on the power station hardware. These power stations are what we call flexible generation.

Interim Power

The second part of the problem is that, like all power plants, and of course Koeberg, there is a need for routine maintenance. When a baseload plant, such as Koeberg, requires routine maintenance, a large rectangular chunk of power is lost from the supply. The power lost is equal to the large rectangular chunk of power that it is designed to provide for 24 hours each day.

If a unit is taken offline for maintenance, what technology should be filling the supply gap? It can’t be supplied by another baseload plant. This would mean that when the unit is back online, that backup baseload power sits idle, which is incredibly expensive. So, we are left with a supply gap, that either needs to be filled with expensive power, or we go on rotational blackouts, also known as load shedding.

The State of Renewables

We cannot ignore the fact that solar and wind have become incredibly cheap per kWh, especially given South Africa’s unrivalled solar and wind resources. If renewables do not become the workhorse of South Africa’s power system, we lose the financial benefit to be gained, and we lose a global competitive advantage in producing cheap, green, products. To capitalize on the benefits of variable renewable power, we need to complement these plants with flexible generation and storage, in the form of gas turbines, hydrogen, and batteries. Coal and nuclear are not compatible with renewables [2].

Affordability and Reliability

A renewables-based system consists of hundreds of plants distributed across the country, as opposed to a few mega-plants located in two or three provinces. The system is inherently more reliable. With renewables, we do not have large chunks of power that, when under maintenance, are unavailable for several months, as is the case with Koeberg Unit 1. We have small, intermittent losses that are much cheaper and easier to fill with flexible generation.

If we keep to the old-fashioned mindset of basing our power system on baseload power, the result is either an expensive power system or a power system that is prone to load-shedding. It’s time to move on, embrace the new way of doing things, and reap the rewards. In South Africa, that reward is greater than in almost every other place on the planet.